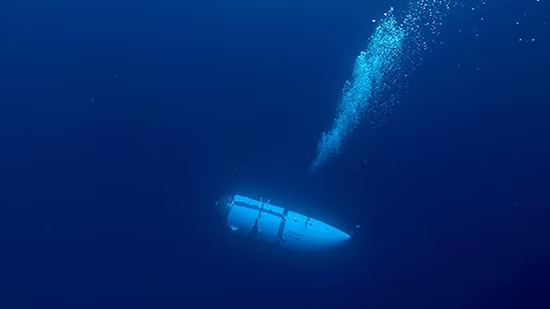

Titan Submersible Disaster: The recent devastating implosion of the Titan submersible has sparked serious questions surrounding its unconventional design and safety precautions. This tragic incident has brought attention to the refusal of the creators to subject the submersible to independent inspections, a common practice in the industry. Experts and former passengers are highlighting the significant risks associated with the Titan submersible and its crew’s expedition.

Table of Contents

Risks Associated with the Expedition and Design Flaws

- Elongated cabin design increased pressure loads in the midsections.

- Fatigue and delamination loads were elevated due to the design.

- Small cracks in the carbon fiber hull eventually led to uncontrollable crack growth.

According to The Guardian, the ill-fated expedition undertaken by the Titan submersible and its crew was fraught with considerable risk. One major concern was the elongated cabin design, intended to accommodate crew and passengers, which led to increased pressure loads in the midsections. As a result, fatigue and delamination loads were elevated, as stated by an associate professor at the University of Plymouth, cited by AP.

Furthermore, the Titan’s carbon fiber hull, measuring 5 inches thick, had already endured repeated stress during approximately two dozen previous dives. These stressors caused small cracks in the hull structure, initially undetectable but eventually reaching a critical point. Experts explain that this led to rapid and uncontrollable crack growth.

Hasty Carbon-Fiber Hull Design

- The company had only six weeks to develop the innovative carbon-fiber hull.

- Carbon composites have limitations under excessive loads or poor design.

- Stress concentrations resulted from the rushed development process.

Business Insider revealed that the company responsible for constructing the groundbreaking carbon-fiber hull of the Titan submersible had only six weeks to develop this innovative design. OceanGate’s CEO, Stockton Rush, admitted to pushing the boundaries by using this specific material. However, industry expert Graham-Jones explains that carbon composites have limitations when subjected to excessive loads or poor design, which can result in stress concentrations.

Lack of Third-Party Scrutiny and Safety Warnings

- OceanGate received warnings about potential safety issues during the submersible’s development phase.

- Former director David Lochridge expressed concerns about inadequate testing and certification processes.

- The absence of external certification and classification raised significant concerns about the vessel’s safety.

During the vessel’s development phase, OceanGate received warnings about potential catastrophic safety issues arising from the lack of third-party scrutiny. In a 2018 lawsuit, David Lochridge, former director of marine operations at OceanGate, expressed concerns that the company’s testing and certification processes were inadequate, putting passengers in extreme danger aboard an experimental submersible. Lochridge advocated for nondestructive testing methods such as ultrasonic scans, but his recommendations were disregarded.

The absence of external certification and classification has raised concerns, with renowned undersea explorer Robert Ballard, discoverer of the Titanic wreckage, describing it as a “smoking gun” in the vessel’s failure. This omission has intensified concerns surrounding the Titan’s size, construction material, and the lack of third-party examination of the prototype.

Conclusion – Titan Submersible Disaster

The implosion of the Titan submersible has prompted an investigation into its design flaws and safety measures. The elongated cabin design and carbon fiber hull have been scrutinized for increasing pressure loads and potential structural vulnerabilities. The rushed development process and absence of third-party inspections have heightened safety concerns, emphasizing the importance of strict quality control measures in the creation of experimental submersibles. As the investigation continues, this tragic incident serves as a stark reminder to prioritize safety and adhere to industry standards in high-risk expeditions.

Do let us know your views on Titan Submersible Disaster in the comment section below.

Source: via

FAQs

1. How did the design of the Titan submersible contribute to its failure?

The elongated cabin design of the Titan submersible increased pressure loads in the midsections, leading to elevated fatigue and delamination loads. Additionally, the carbon fiber hull, which had already experienced stress from previous dives, developed undetectable cracks that eventually caused rapid and uncontrollable crack growth.

2. What materials were used in constructing the Titan submersible?

The Titan submersible was constructed using a groundbreaking carbon-fiber hull that measured 5 inches thick. However, the hasty development process and limited timeframe for design and construction raised concerns about the hull’s ability to withstand excessive loads.

3. Were there any warnings about the safety of the Titan submersible?

Yes, during the development phase, there were warnings about potential safety issues due to the lack of third-party scrutiny. Former director of marine operations at OceanGate, David Lochridge, expressed concerns about inadequate testing and certification processes, which were disregarded by the company.

4. Why is the absence of third-party certification a concern?

The absence of third-party certification and classification raises concerns about the safety and reliability of the Titan submersible. Independent scrutiny is crucial to identify potential flaws and ensure that high safety standards are met in the development of experimental submersibles.

5. What lessons can be learned from the Titan submersible disaster?

The Titan submersible disaster highlights the importance of prioritizing safety and adhering to industry standards in high-risk expeditions. It underscores the need for thorough inspections, quality control measures, and external certifications to identify and address potential design flaws and ensure the safety of passengers and crew.